Op-Gear

Like penstocks the world of op-gear can be confusing, but it can be broken down to a few items

Direction of Operaiton

Unlike most threads, penstoxks and valave typically have a left hand thread, such that the hand wheel closes the unti when turned clock wise.

Clockwise to close: typical left hand thread

Anti-clockwise to close: non-typical right hand thread.

Operaiton

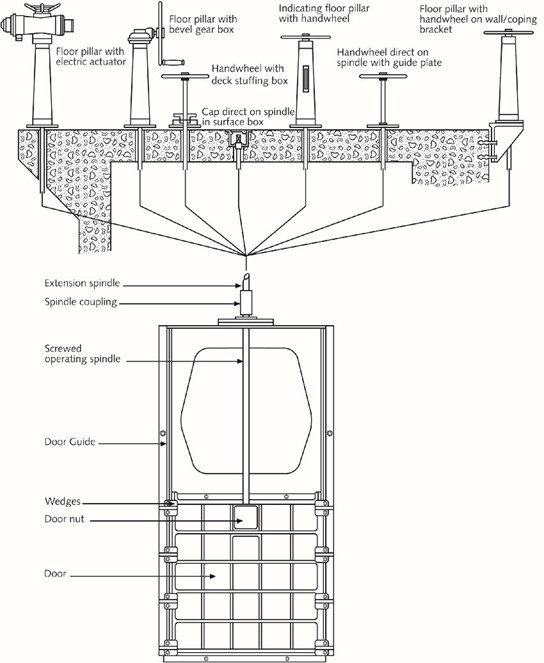

Non rising stems: Rotate through a nut in the penstock door. The screwed portion of the stem at the bottom is probably immersed in the water, effluent etc.

Rising stems: Are connected to the penstock door and work through a revolving nut located in the operating gear. The screw thread at the top of the stem is generally not immersed and is readily accessible for maintenance.

Operating Force

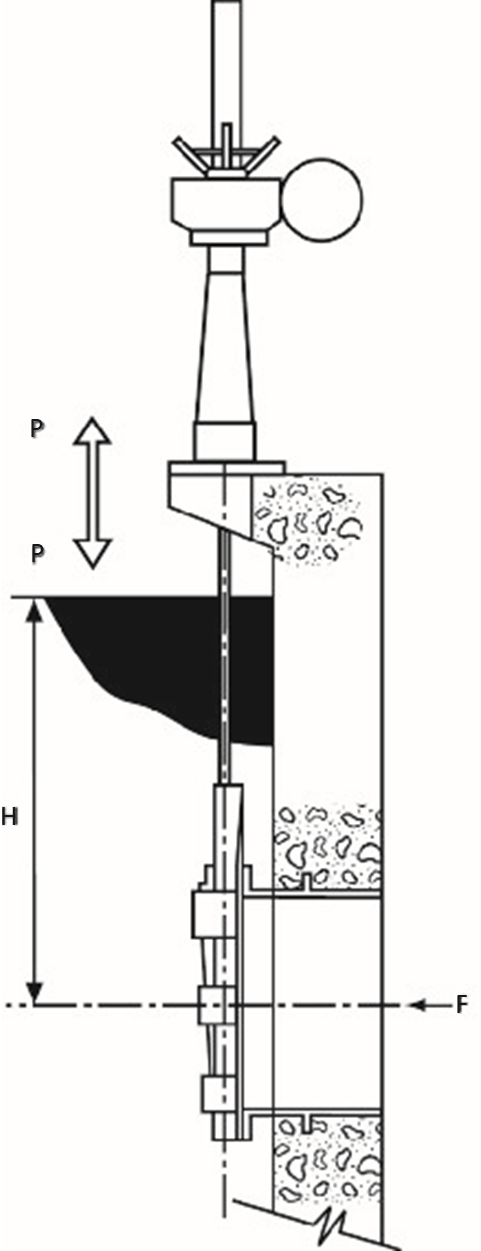

This is the force required to open and close the penstock door. The civil engineering structure will experience this load where the penstock operating device is remote.

However the civil engineering structure will not experience this force if the penstock operating device is connected directly to the penstock i.e . the thrust reaction is taken at the top of the penstock frame.

Actuator

With all valves and penstocks, we have typically 3 options:

Manual operation: the unit is opened / closed via a hand wheel. This system is ideal when operation is infrequent or in a location without power. On larger units the number of turns to operate need to be considered here as the unit will require high gearing in order to reduce the effort by the operator i.e. many revolutions of the hand wheel.

Actuated operation: the unit is opened / closed by mechanical means (electric, hydraulic or pneumatic). This system is ideal when the operation is required relatively frequently and tied into a wider system. The drawback here is the cost of implementation and the requirement for power / control at the unit.

Modulation Operation: the unit is opened / closed at a high frequency (typically greater than 3 times per minuet). This system is typically employed when the unit is part of a process control system and required more robust design of operating gear to withstand the increased cyclic load on the system.

Operating Head

Operating Head for penstocks are specified to the invert in BS 7775. These heads can be used conservatively for these calculations. More accurately, the head at the centre of the door should be used for determining the op-gear, this is the head at the invert less half the door depth.

The hydrostatic load F is the force of the water against the penstock door, which will be transferred to the civil structure by the penstock frame. This force acts perpendicular to the frame.

For operation the maximum differential head at the centre of the door should be considered. This should be the worst case in which the unit is intended to operate.

Bespoke Op-Gear Solutions

When the standard range just won't do you’ve come to the right place.

The core of our business is the design and manufacturer of penstocks for the harshest environments to the most exacting standards.

Having delivered projects in the UK, UAE, Qatar, Sudi Arabia. We know what it takes to satisfy even the most challenging brief.

Whether it be an innovative re-imagining of existing stock or operation of a remote unit using solar panels our engineers relish the challenge of making the system work inside the bounds you have set.

Having a vast experience on tap across many manufacturers we understand the capabilities of the unts in the market and can help you extract the full potential of your system

Costs and timelines in these projects will be based on the specification.

Delivery = 8 weeks +

Manual to Automated converison

When you need to bring your existing equipment into the 21st century come to the right place.

Having delivered projects in the around the world, we understand the design and limitations of the existing stock of units in the market. Using our knowledge and experience we can deliver the correct equipment to upgrade your existing stock such that it can be connected to the networks of today and the future.

Our packages typically include new, stems, drive nuts, guide blocks and pillars such that your penstock or valve will be operating like new from day one.

Having a vast experience on tap across many manufacturers we understand the capabilities of the unts in the market and can help you extract the full potential of your system.

Costs and timelines in these projects will be based on the specification.

Delivery: 6 weeks

Direct to Remote Conversions

When you need to bring your operation to the right place you’ve come to the right pace.

Having delivered projects in the around the world, we understand the design and limitations of the existing stock of units in the market. Using our knowledge and experience we can deliver the correct equipment to bring the operation of your existing stock to the right place.

Our packages typically include new, couplings, stems, guides, guide blocks and pillars such that your penstock or valve will be operating like new from day one.

Having a vast experience on tap across many manufacturers we understand the capabilities of the unts in the market and can help you extract the full potential of your system.

Costs and timelines in these projects will be based on the specification.